An Aluminum Ceiling represents a modern ceiling solution engineered to offer durability, aesthetic flexibility, and long-term performance across residential, commercial, and industrial environments. Built from lightweight yet strong aluminium alloys, this type of ceiling has become a preferred choice in contemporary architecture because it elegantly solves challenges such as moisture resistance, structural stability, fire safety, and ease of maintenance. As design requirements shift toward cleaner lines and high-efficiency building materials, Aluminum Ceiling systems continue to expand in both functionality and style. Understanding what an Aluminum Ceiling is—and how its structure, benefits, and installation processes work—helps property owners, designers, and builders make informed decisions for new builds and renovations.

Contents

What Defines an Aluminum Ceiling

Key Material Composition and Performance Features

Common Types of Aluminum Ceiling Systems

Structural Advantages of Using Aluminium for Ceilings

Applications of Aluminum Ceilings in Different Environments

Design Options, Textures, and Surface Treatments

Installation Process and Maintenance Considerations

How Aluminum Ceilings Compare to Other Ceiling Materials

Conclusion

FAQ

What Defines an Aluminum Ceiling

An Aluminum Ceiling is a ceiling system constructed from aluminium panels, planks, or tiles designed to provide a long-lasting and visually appealing overhead finish. What distinguishes an Aluminum Ceiling from other ceiling materials is its combination of corrosion resistance, low weight, and structural adaptability. Modern Aluminum Ceilings frequently incorporate modular designs, meaning panels can be easily replaced, reconfigured, or removed for access to utilities behind the ceiling. This makes them ideal solutions for buildings requiring frequent system maintenance, such as offices, airports, malls, and healthcare facilities. The defining intention behind the Aluminum Ceiling concept is to create a ceiling structure that resists degradation while consistently maintaining its shape, appearance, and performance under demanding environmental conditions.

Key Material Composition and Performance Features

Aluminum Ceilings are manufactured using premium-grade aluminium alloys, often combined with protective coatings such as PVDF, polyester powder coating, or anodized films. These layers enhance resistance to weather, chemicals, and UV exposure. The inherent properties of aluminium—such as high strength-to-weight ratio and natural rust resistance—create predictable performance over many years. From an insulation perspective, aluminium reflects radiant heat, helping improve energy efficiency in controlled environments. Its non-porous surface naturally inhibits mold and bacterial growth, supporting hygienic standards required in kitchens, laboratories, and medical facilities. When assessing what an Aluminum Ceiling truly offers, performance characteristics stand at its core: stability, longevity, and reliability under varying environmental pressures.

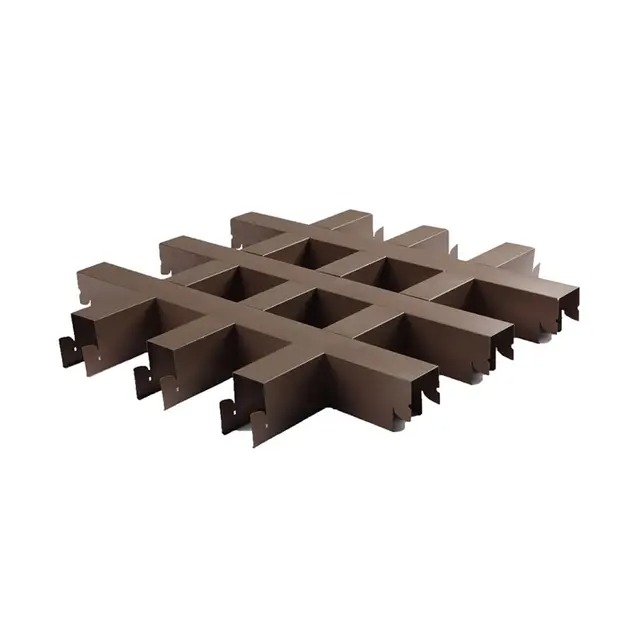

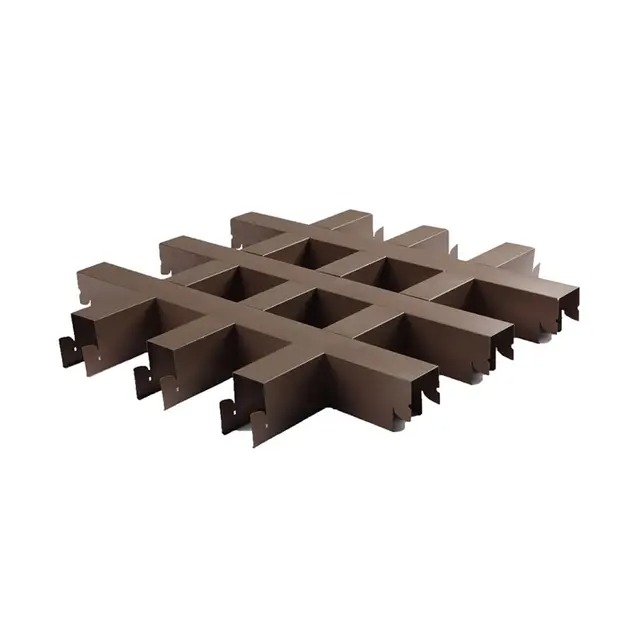

Common Types of Aluminum Ceiling Systems

The Aluminum Ceiling market includes a range of systems engineered to match different architectural needs. Each type provides unique benefits depending on acoustic goals, design aesthetics, or installation requirements. Understanding these variations helps clarify how Aluminum Ceilings fit into modern buildings. The most common systems include clip-in tiles for seamless finishes, lay-in panels for accessible ceilings, linear slats for acoustic control, and baffle ceilings for open, layered visuals. These systems utilize different installation frameworks, such as concealed suspension grids or visible T-grids, allowing architects to control appearance and function without compromising structural integrity. Choosing the right Aluminum Ceiling type often starts with identifying whether the space needs high accessibility, acoustic performance, or expressive visual patterns.

Table 1: Common Aluminum Ceiling Types and Their Core Uses

| Aluminum Ceiling Type | Visual Style | Core Applications |

| Clip-in tiles | Smooth, seamless | Offices, airports, corridors |

| Lay-in panels | Grid-based pattern | Commercial buildings, retail |

| Linear slats | Long, narrow planks | Hotels, lobbies, residences |

| Baffle ceilings | Vertical fins, open space | Auditoriums, stations, malls |

Structural Advantages of Using Aluminium for Ceilings

The primary advantage of an Aluminum Ceiling is durability. Aluminium naturally resists corrosion, making it an ideal material for high-humidity or high-traffic environments. Unlike gypsum-based boards, aluminium does not warp, rot, or crack when exposed to moisture or thermal changes. Its lightweight structure reduces stress on overhead framing, improving safety and simplifying installation. Aluminum Ceilings also offer inherent fire resistance, as the metal does not ignite or support flame spread. This characteristic significantly increases building safety ratings and reduces long-term risks. Noise control can be achieved by integrating perforated aluminium panels with acoustic backings, creating ceilings that absorb sound without adding significant weight. Together, these advantages define Aluminum Ceilings as high-performance architectural solutions.

Applications of Aluminum Ceilings in Different Environments

Due to their adaptable structure, Aluminum Ceilings support a broad range of architectural conditions. Commercial buildings use Aluminum Ceilings to maintain a clean, professional appearance while supporting integrated lighting, HVAC vents, and sprinkler systems. Industrial settings benefit from aluminium’s resistance to chemicals and heat, especially in factories, laboratories, or food-processing plants. Residential environments use Aluminum Ceilings for kitchens, bathrooms, verandas, and modern interior designs where durability and style must coexist. Public infrastructure—such as airports, bus stations, and hospitals—relies heavily on Aluminum Ceilings for their accessibility and rapid maintenance capabilities, ensuring operational continuity. The ability to blend performance, longevity, and contemporary design explains why Aluminum Ceilings appear across diverse architectural sectors.

Design Options, Textures, and Surface Treatments

One of the strongest attributes of an Aluminum Ceiling is design freedom. Aluminium panels can be shaped, perforated, curved, or embossed to match almost any architectural vision. Surface treatments such as powder coating, anodizing, or wood-grain transfer printing allow Aluminum Ceilings to mimic natural materials without sacrificing durability. Perforation patterns support acoustic performance while introducing decorative elements that enhance interior ambiance. Lighting integration—such as recessed lighting, LED strips, or panel-mounted fixtures—can be seamlessly merged into Aluminum Ceiling structures. Designers can select matte, gloss, metallic, or textured finishes depending on the desired mood. With increasingly sophisticated coating technologies, Aluminum Ceilings can achieve both minimalistic uniformity and dramatic architectural expression.

Table 2: Popular Aluminum Ceiling Finishes and Their Benefits

| Finish Type | Appearance | Benefit |

| Powder-coated | Smooth, uniform | Highly durable and color-stable |

| Anodized | Metallic, reflective | Corrosion-resistant, elegant |

| Wood-grain transfer | Natural wood look | Aesthetic warmth without wood maintenance |

| Textured embossing | Patterned surface | Adds depth and hides minor imperfections |

Installation Process and Maintenance Considerations

Installing an Aluminum Ceiling involves preparing the structural framework, aligning suspension systems, and securely attaching panels. Compared with heavier materials, aluminium allows installers to work efficiently and with reduced physical strain. Clip-in systems require precise alignment to ensure a flush finish, while lay-in ceilings demand accurate grid assembly. In both cases, aluminium’s light weight minimizes risks during handling. Maintenance is particularly straightforward: most Aluminum Ceilings need only periodic dusting or gentle cleaning with mild detergents. Panels can be removed individually for access to wiring, ducts, or plumbing behind the ceiling, reducing downtime in commercial spaces. Because aluminium is resistant to stains, mold, and corrosion, maintenance remains minimal over the ceiling’s lifetime, enhancing long-term cost efficiency.

How Aluminum Ceilings Compare to Other Ceiling Materials

When evaluating what an Aluminum Ceiling offers, comparisons to other ceiling materials—such as gypsum boards, PVC panels, and wood—highlight its major advantages. Gypsum ceilings are affordable but vulnerable to moisture and cracking. PVC ceilings provide water resistance but lack heat stability and long-term durability. Wood delivers warm aesthetics but requires continuous maintenance and is sensitive to humidity. Aluminium stands out by delivering lasting performance across moisture, heat, fire, and structural challenges. Its recyclability also places Aluminum Ceilings ahead in sustainability, reducing environmental impact during renovation cycles. Although Aluminum Ceilings may require a higher initial investment, their extended lifespan, reduced maintenance, and enhanced safety often lead to lower overall lifetime costs.

Conclusion

An Aluminum Ceiling is a modern ceiling system designed to deliver long-term durability, flexible design possibilities, and high-performance functionality across a wide range of building environments. Its resistance to corrosion, fire, moisture, and deformation makes it one of the most reliable ceiling solutions available today. From commercial buildings to residential interiors and large public spaces, Aluminum Ceilings combine structural strength with aesthetic versatility, providing property owners and architects with a forward-thinking alternative to traditional ceiling materials. Understanding what an Aluminum Ceiling truly is—its material composition, design options, installation requirements, and comparative benefits—empowers decision-makers to select ceiling systems that offer lasting value, safety, and architectural clarity.

FAQ

1. Are Aluminum Ceilings suitable for bathrooms and kitchens?

Yes. Aluminum Ceilings are highly suitable for humid spaces because they resist moisture, mold, and corrosion far better than gypsum or wood alternatives.

2. Can an Aluminum Ceiling be customized in color and texture?

Absolutely. Through powder coating, anodizing, and printing technologies, Aluminum Ceilings can achieve countless colors, textures, and patterns, including realistic wood finishes.

3. Do Aluminum Ceilings improve fire safety?

Yes. Aluminium is a non-combustible material that does not ignite, helping buildings achieve better fire-safety ratings.

4. Are Aluminum Ceilings difficult to maintain?

No. Maintenance is minimal—typically requiring only light cleaning. Panels can also be removed individually for quick access to utilities behind the ceiling.

5. How long do Aluminum Ceilings last?

With proper installation and basic cleaning, Aluminum Ceilings can last several decades without warping, cracking, or losing color.